Worm Wheel Worm Lug Butterfly Valve Worm Wheel Worm Lug Butterfly Valve is mainly divided into metal seal and elastic seal, belonging to concentric center line butterfly valve. The torque required for switching is reduced by the worm wheel. Compared with handle lug butterfly valve, it is more labor-saving in the switching process during use

Application and characteristics of worm gear switch lug butterfly valve  4 inch lug butterfly valve - The worm gear operated lug butterfly valve consists of a rubber sealed butterfly valve and a carbon steel or stainless steel valve plate and stem. Suitable for water supply, drainage, and gas pipelines in food, medicine, chemical, petroleum, power, textile, paper, and other industries with temperatures ranging from 80 to 120 ℃. Its main characteristics are:

4 inch lug butterfly valve - The worm gear operated lug butterfly valve consists of a rubber sealed butterfly valve and a carbon steel or stainless steel valve plate and stem. Suitable for water supply, drainage, and gas pipelines in food, medicine, chemical, petroleum, power, textile, paper, and other industries with temperatures ranging from 80 to 120 ℃. Its main characteristics are:

The design is novel and reasonable, the structure is unique, the weight is light, and the opening and closing are fast. Small operating torque, easy to operate, labor-saving, and intelligent. It can be installed in any location and is easy to maintain. The seals are replaceable, reliable in sealing performance, and can achieve bi-directional sealing with zero leakage. Sealing materials have the characteristics of aging resistance, weak corrosion resistance, and long service life. The large diameter gear operated lug butterfly valve of ASIAV series can be operated from 1 inch to 60 inches. We will make it into a large-diameter multi-stage gear operation to make valve switching easier.

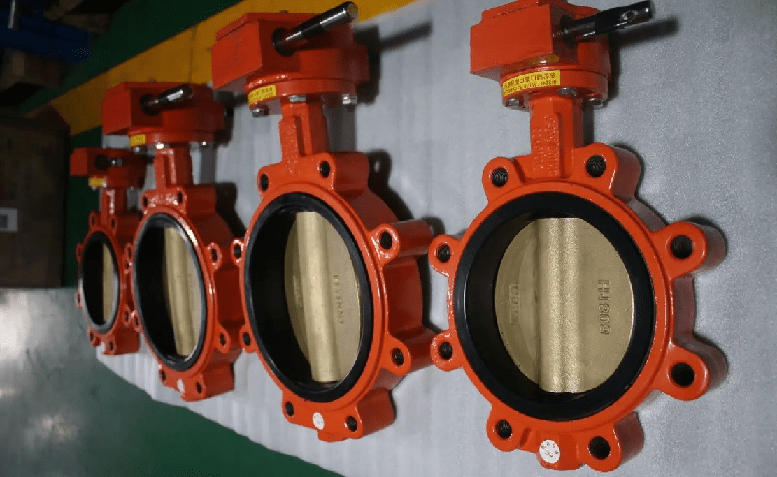

00032 inch Lug Butterfly Valve - Worm Wheel Cast Steel Worm Switch Lug Butterfly Valve ASIAV Series Worm Wheel Lug Butterfly Valve can be made of materials such as ductile iron, cast steel, aluminum alloy, etc

cast steel worm gear switch lug butterfly valve gear transmission lug butterfly valve ASIAV series worm gear switch lug butterfly valve can be customized into various colors and standards - such as ANSI lug butterfly valve, JIS lug butterfly valve, EN lug butterfly valve, etc

cast steel worm gear switch lug butterfly valve gear transmission lug butterfly valve ASIAV series worm gear switch lug butterfly valve can be customized into various colors and standards - such as ANSI lug butterfly valve, JIS lug butterfly valve, EN lug butterfly valve, etc

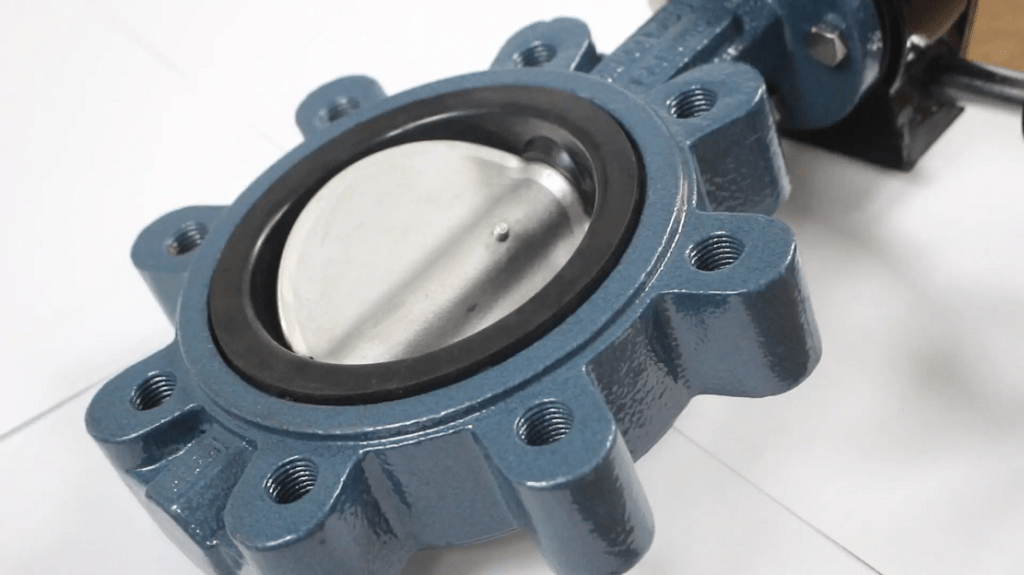

Chinese gear operated worm gear lug butterfly valve with bi-directional sealing and zero leakage. The overall design of the fully lined rubber valve seat completely isolates the valve body from the medium in the pipeline. Since the valve body is not in contact with the medium, there is no need to consider the corrosion resistance of the valve body material when the medium inside the pipeline is corrosive. Dry shaft design ensures complete isolation between the valve stem and the medium in the pipeline, without considering the corrosion resistance of the valve shaft material. Only standard valve stem materials need to be selected. Low operating torque. Lightweight, easy to install and maintain. The full bore design greatly improves the flow coefficient and meets the efficient flow of the medium inside the pipeline.

Chinese gear operated worm gear lug butterfly valve with bi-directional sealing and zero leakage. The overall design of the fully lined rubber valve seat completely isolates the valve body from the medium in the pipeline. Since the valve body is not in contact with the medium, there is no need to consider the corrosion resistance of the valve body material when the medium inside the pipeline is corrosive. Dry shaft design ensures complete isolation between the valve stem and the medium in the pipeline, without considering the corrosion resistance of the valve shaft material. Only standard valve stem materials need to be selected. Low operating torque. Lightweight, easy to install and maintain. The full bore design greatly improves the flow coefficient and meets the efficient flow of the medium inside the pipeline.