The large-diameter two-way pressure butterfly valve is a top mounted metal hard sealed butterfly valve that is easy to install and maintain online. When the valve needs maintenance, there is no need to remove it from the pipeline. As long as the upper cover is opened, the valve stem and butterfly plate can be removed from the valve body cavity for maintenance, making maintenance easier and more convenient. At present, the hard sealed butterfly valves produced domestically and internationally are side mounted with butterfly plates; Once a malfunction occurs during use, maintenance is required; The medium in the pipeline must be closed, and the entire valve can only be repaired after being removed from the pipeline. The maintenance is difficult and time-consuming, which affects the normal operation of the pipeline system; Therefore, when professionally designed and developed top mounted metal hard sealed butterfly valves are installed on pipelines, the valve body, butterfly plate, elastic motion compensation valve seat, valve stem, and composite multi-layer elastic sealing ring can be easily disassembled.

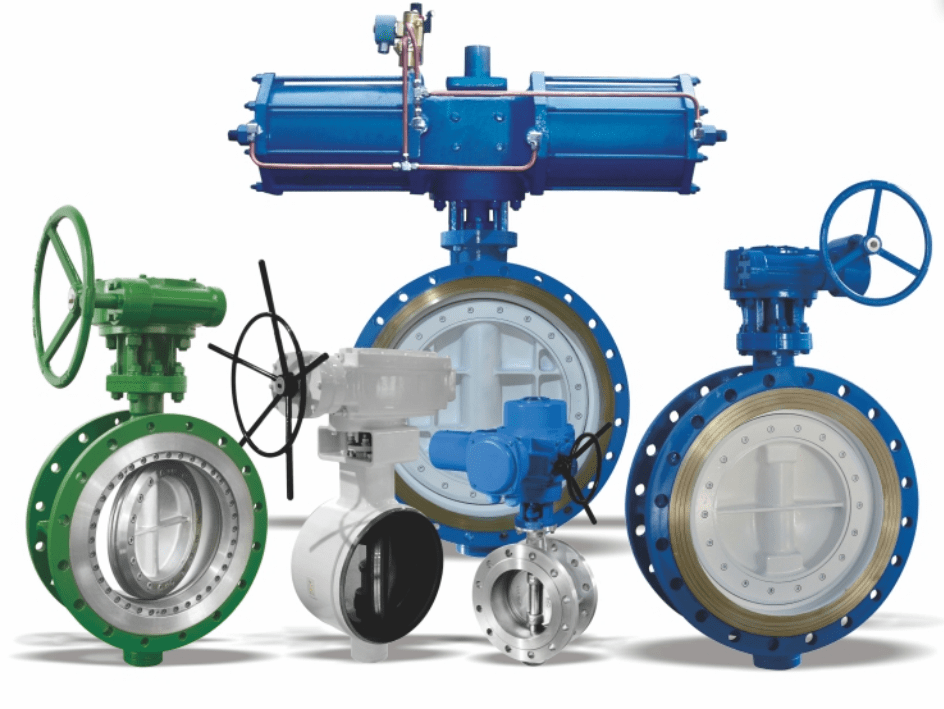

Soft sealed Butterfly Valve

Soft sealed Butterfly Valve

The characteristic of this valve is that it can be inspected and maintained online after the device system is depressurized during operation. When repairing, simply open the valve cover, remove the butterfly plate, elastic motion compensation valve seat and other accessories for repair or replacement, without removing the entire valve from the pipeline. Valves can be reused to save energy.

Three eccentric hard seal butterfly valve

Three eccentric hard seal butterfly valve

The product features of two-way pressure butterfly valve are easy to maintain: the large-diameter two-way pressure butterfly valve is a top mounted structure. When the valve needs maintenance, it does not need to be removed from the pipeline. Open the upper cover, remove the valve stem and butterfly plate from the valve body cavity, and take out the automatic compensating valve seat for maintenance. The characteristics of this switch are fast, 90 degree reciprocating rotation, and low driving torque. Used for cutting, connecting, and regulating media in pipelines. Has good fluid control characteristics and sealing performance. The butterfly plate of the large-diameter two-way pressure butterfly valve adopts a streamlined design, which reduces fluid resistance loss, increases the load surface of the valve body cavity, reduces flow resistance, and increases the fluid load surface; High compressive strength. The valve stem shaft sleeve is made of self-lubricating tin bronze, with a low friction coefficient (<0.16) and flexible opening and closing. The valve stem of the large-diameter metal hard sealed butterfly valve is a through stem structure. The valve stem has undergone special treatment, with strong wear resistance, good comprehensive mechanical properties, corrosion resistance, and extremely high scratch resistance. When the top mounted butterfly valve is opened and closed, the valve stem only rotates and does not rise or fall. The valve stem packing is not easily damaged and the seal is reliable. It is fixed to the conical pin of the butterfly plate, and the extended end is designed to prevent the valve stem from bursting in case of accidental breakage at the connection between the valve stem and the butterfly plate. Anti particle wear: The movement of the top mounted two-way sealed butterfly valve disc has wiping performance and a cleaning effect between the multi-stage sealing ring and the movable valve seat on the valve body, which effectively removes granular crystals, dirt, fibers, and other substances crystallized on the sealing surface of the movable valve seat; The active valve seat sealing ring is made of high toughness and wear-resistant stainless steel, which has undergone special treatment and has strong wear resistance. It has good comprehensive mechanical and corrosion resistance. It is very scratch resistant. The butterfly plate sealing ring is made of soft and hard wear-resistant sealing plates, which have the dual advantages of metal hard sealing and elastic sealing. Bidirectional compression, reliable sealing, and long service life. Has excellent sealing performance at low and high temperatures. Long service life, easy switching: effectively and reasonably reduces eccentricity, greatly reducing the torque of the valve; There are no vulnerable parts. Due to the eccentric effect, the sealing surface between the butterfly plate and the movable valve seat is completely separated during the valve opening and closing process. The valve rotates frictionlessly with low torque. The automatic compensation function of the valve greatly improves its service life and is easy to operate; Valve body sealing surface; Adopting welded stainless steel and cobalt based hard alloy, the sealing surface is wear-resistant, high temperature resistant, and has a long service life. Friction free switch: According to the principle of three-dimensional eccentricity, the sealing surface of the butterfly plate only moves towards the sealing surface of the valve body with three-dimensional eccentric displacement in an instant after the last minute. Under the action of eccentricity, the sealing surface of the butterfly plate and the sealing surface of the valve body become increasingly tight. Therefore, the sealing surface of the butterfly plate is in good close contact with the sealing surface of the valve body, achieving good sealing effect and reliable sealing performance; When the valve is opened, the butterfly plate only needs to rotate a small angle (2-3) under the action of eccentricity, and the sealing surface of the butterfly plate and the sealing surface of the valve body will be completely separated The butterfly plate sealing surface and the valve body sealing surface will not generate friction, and the valve has a long service life. Bidirectional pressure automatic compensation: When applying pressure from left to right, using the principle of signal eccentricity, the butterfly plate and valve body become increasingly tight, thereby achieving good sealing; When applying pressure from right to left as shown in the figure, when the pressure pushes the automatic compensating valve seat, the automatic compensating valve seat will automatically press against the butterfly plate. When the pressure is high, the automatic compensation valve seat will press against the butterfly plate, thereby achieving good sealing; Top mounted two-way sealed butterfly valve, two-way pressure can also reach 100% zero leakage; In long-term use, if the automatic compensation valve seat seal and butterfly plate seal are worn or damaged, the automatic compensation valve seat will automatically advance to the butterfly plate under pressure. When the butterfly plate is pressed in reverse, the automatic compensation valve seat moves forward under pressure, thereby achieving good automatic compensation function.