What is a metal hard seal butterfly valve? The metal hard seal butterfly valve is mainly composed of a valve body, a butterfly plate, a valve shaft, a valve body sealing ring, a butterfly plate sealing ring, a shaft sleeve, a self-lubricating bearing, and a driving device. The high-performance metal hard sealed butterfly valve drives the valve shaft to rotate through various driving devices, and drives the butterfly plate to rotate within 90 degrees through the pin shaft, so that the butterfly plate is in the open or closed state, thereby achieving the purpose of connection or disconnection. Widely used in metallurgy, hydropower, thermal power, heating, urban water supply and drainage, farmland irrigation and drainage industries. Applicable media include gas, steam, air, and water in pipeline systems.

What is a metal hard sealed butterfly valve

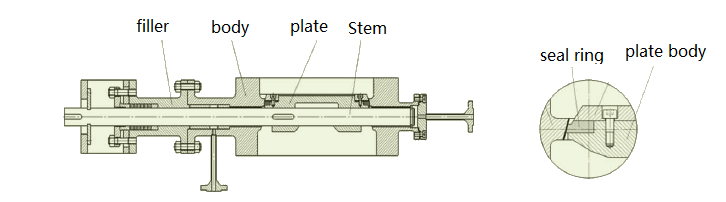

Internal structure of metal sealed butterfly valve

Structural characteristics of metal sealed butterfly valve: ① Unique three-way eccentric design, which ensures frictionless transmission of the sealing surface and extends the service life of the valve. ② Elastic sealing is generated by torque The clever wedge-shaped design enables the valve to have an automatic sealing function that closes tighter and tighter, with compensation between the sealing surfaces and zero leakage Small size, light weight, easy operation, and convenient installation. ⑤ According to user requirements, pneumatic and electric devices can be configured to meet the needs of remote control and program control The replacement material can be used for various media and can be used as an inner lining for corrosion prevention (F46, gxpp, Po, etc.) The sealing ring is made of stainless steel, which has the dual advantages of metal hard sealing and elastic sealing. It has excellent sealing performance at both low and high temperatures.

The difference between metal hard seal butterfly valve and rubber seal butterfly valve: What is the metal hard seal butterfly valve series? The disadvantage of rubber seal butterfly valve is that when used for throttling, improper use can cause cavitation, resulting in rubber seat peeling and damage. For this reason, metal sealed butterfly valves, metal hard sealed butterfly valves with eccentric metal sealing structures, metal to metal sealing forms, replaceable metal sealing rings for metal seals, and stainless steel and graphite composite plate sealing rings have been developed internationally. The high-performance elastic metal sealed butterfly valve adopts a double eccentric and special oblique cone elliptical sealing structure. Solved the problem of sliding contact friction on the sealing surface of traditional eccentric butterfly valves during opening and closing from 0 to 10, and achieved the effect of separating the sealing surface during opening and closing. Instantly close, thereby extending the service life and achieving optimal sealing performance. In addition to flange and clamp connections, hard sealed butterfly valves also have lug butterfly valves. You can go to our valve selection to find what you need. If not, you can contact us and you will be satisfied