There is a certain relationship between ball valves and PTFE (polytetrafluoroethylene), and PTFE or its related materials are usually used in the sealing components of ball valves. The following is the relationship between ball valves and PTFE:

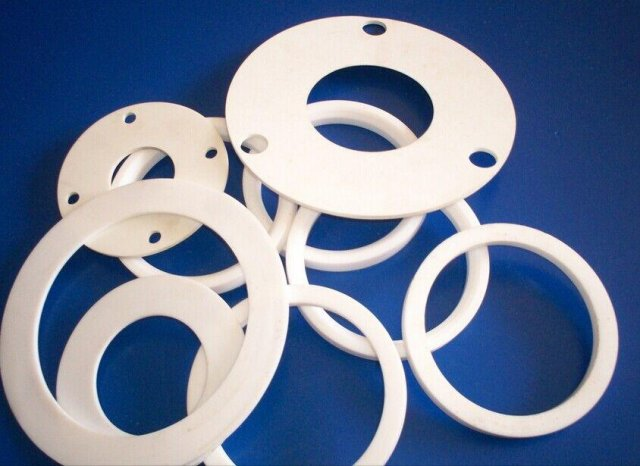

Sealing material: Ball valves are typically used to control fluid flow, so effective sealing needs to be provided between the valve body and spool to prevent fluid leakage. PTFE is an excellent sealing material due to its extremely low coefficient of friction and excellent chemical corrosion resistance. PTFE sealing rings or gaskets are commonly used as sealing components for ball valves to ensure reliable sealing performance.

Temperature range: PTFE has excellent high temperature resistance and can work in a wide temperature range, from low to high temperatures. This makes PTFE an ideal choice for ball valve sealing components, as ball valves may need to operate under various temperature conditions.

Chemical corrosion resistance: PTFE has excellent corrosion resistance to various chemicals, which means it can be used for ball valve applications that handle corrosive media without damage.

Friction reduction: The low friction coefficient of PTFE makes the operation of the ball valve smoother, reduces the need for operating force, and extends the life of the ball valve.

In summary, ball valves typically use PTFE or its related polymer materials as sealing components to ensure reliable sealing performance, temperature resistance, and chemical stability of the valve. This enables ball valves to be widely used in various industrial and fluid control applications.