Pneumatic aluminum alloy butterfly valve specifications Pneumatic aluminum alloy butterfly valve uses air as the driving force for the actuator, and switches between single acting or double acting actuators. After assembly, the locator can be used for 4-20mA simulation adjustment of valve opening.

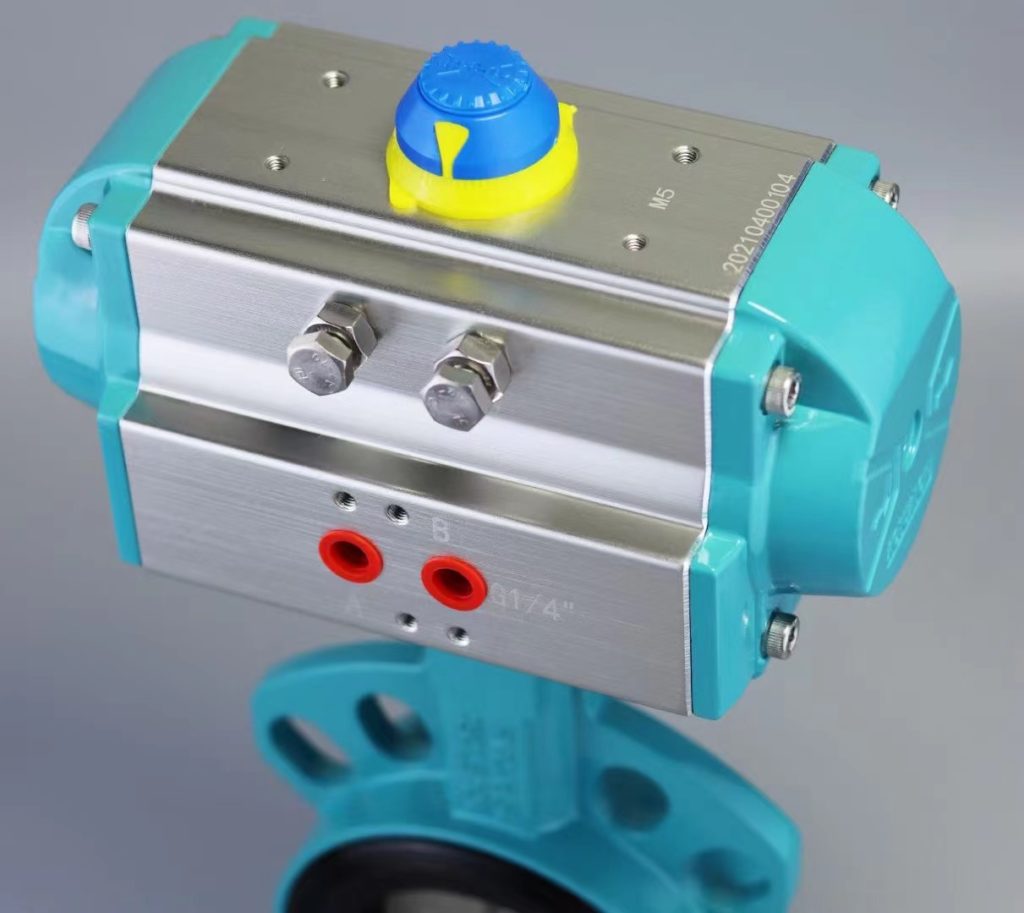

The pneumatic aluminum alloy butterfly valve  actuator is made of aluminum alloy and stainless steel screws, coated with epoxy resin on the outside, and equipped with a switch position indicator on the top. It has double acting without springs and single acting with springs on both sides. The actuator can control the opening or closing of the butterfly valve through the spring reaction force

actuator is made of aluminum alloy and stainless steel screws, coated with epoxy resin on the outside, and equipped with a switch position indicator on the top. It has double acting without springs and single acting with springs on both sides. The actuator can control the opening or closing of the butterfly valve through the spring reaction force

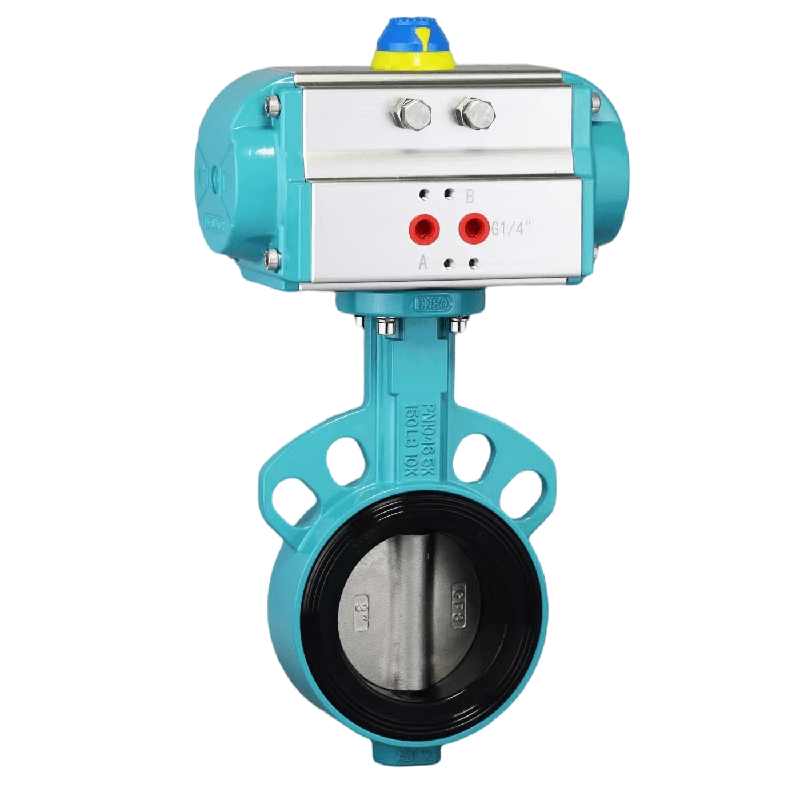

Pneumatic actuator clamp butterfly valve  valve body detail drawing. The flange connection plate on the valve body of the pneumatic clamp butterfly valve complies with ISO 5211 standard and is fully suitable for various actuators and drive devices.

valve body detail drawing. The flange connection plate on the valve body of the pneumatic clamp butterfly valve complies with ISO 5211 standard and is fully suitable for various actuators and drive devices.

The valve body can be made of aluminum alloy, ductile iron, cast steel, stainless steel, etc

The valve plate can be made of stainless steel 304, 316, 2507, lined valve plate, etc

The valve seat can be made of PTFE, EPDM, VITON, etc

Pneumatic butterfly valve actuator type: double acting, single acting

Valve body material: aluminum alloy, ductile iron, cast steel, stainless steel, etc

Valve plate material: stainless steel, rubber lining, fluorine lining, etc

Valve seat material: EPDM, PTFE, NBR, VITON, etc

Upper flange standard: ISO 5211

Optional accessories: Positioner, Air Direction Control Valve, Air Filter Regulator, Limit Switch

The connection dimensions of our pneumatic aluminum alloy butterfly valve can adopt standards from the United States, Europe, Japan, Germany, and other countries.

The pneumatic butterfly valve can be perfectly controlled by injecting 3-7KG of air supply pressure into the cylinder, and the opening and closing speed is within 3 seconds!