It consists of a 3810 series (PSL series) electric actuator and a small flow regulating valve body. The actuator contains feeding function and accepts a unified 4-20mA or 1-5V · DC standard signal. It converts the current signal into a corresponding linear displacement, automatically controls the opening, and achieves continuous adjustment of process parameters such as pressure, flow rate, temperature, and liquid level of the fluid in the pipeline. It is a small-diameter regulating valve specifically developed for small flow regulation. It has the characteristics of small size, light weight, high performance, and precise control for small flow rates. When the electric small flow regulating valve cannot regulate the clean medium, attention should be paid to the problem of small throttling clearance and the prevention of blockage. Suitable for regulating the main flow of liquid, steam and other media.

1. Main technical parameters of electric small flow regulating valve

Valve body form

Straight through casting and forging valve body

Nominal diameter

DN15~25mm

Valve seat diameter

Dn3~25mm

Nominal pressure

PN 1.6、2.5、4.0、6.4、10.0、16.0 MPa

Connection form

Welding (SW BW), threading (applicable to flanges within 1 inch)

Valve cover form

Standard Type -17~+250 ℃, High Temperature Type+250~+450 ℃, Low Temperature Type -60~-196 ℃, Bellows Sealed Type -40~+350 ℃

Cover type

Bolt compression type

Sealing packing

V-shaped PTFE packing, PTFE impregnated asbestos packing, asbestos textile packing, graphite packing

body material

38136;; 38050; WCB, not 38152; 38050; CF8, CF8M, CF3, CF3M)

2. Valve internals

Valve core form

Single seat plunger type valve core

Traffic characteristics

Linear, equal percentage

Valve core material

Stainless steel (304, 304L, 316, 316L)

3. Actuator

Model of actuator

3810L series, PSL series and imported actuators

Main technical parameters

Power supply voltage: 220V/50Hz, input signal: 4-20mA or 1-5V · DC, output signal: 4-20mA · DC

Protection level: IP55, explosion-proof mark: Exd Ⅱ BT4, manual operation function: handle

Environmental temperature: -25~+70 ℃, environmental humidity: 95%

3、 Performance indicators

project

Indicator value

Basic error%

Equipped with 3810L2.0; Equipped with PSL1.0

Return difference%

Equipped with 381L 2.0; Equipped with PSL1.0

Dead zone%

one

Constant point deviation%

Electric opening

Starting point 2.5

Endpoint 2.5

Starting point 2.5

Endpoint 2.5

Electricity off

Starting point

two point five

End

two point five

Rated travel deviation%

two point five

Leakage rate L/h

0.01% rated capacity of valve

Adjustable range R

50:1

4、 Rated flow coefficient Kv, allowable pressure difference

Nominal diameter DN

G3/8"、 1/2"、 G3/4"、 G1'

Valve seat diameter dN

three

four

five

six

seven

eight

nine

ten

eleven

twelve

Rated flow coefficient KV

zero point zero eight

zero point one two

zero point two zero

zero point three two

zero point five zero

zero point eight zero

one

one point four zero

one point five five

one point eight five

Rated travel

ten

ten

ten

Allowable pressure difference (MPa)

Nominal pressure

5、 Main technical data

1. Main technical performance indicators

project

index

Leakage rate

Single seat: metal valve seat: Class IV, 10-4 below rated flow; soft valve seat: Class VI, 10-7 below rated flow

Sleeve: Single sealed type IV grade, less than 10-4 of rated flow; Double sealed type III, less than 10-3 of rated flow.

Compliant with GB4213-92 standard

Basic error

2.5%

Return difference

2%

Dead zone

3%

Always point deviation

2.5%

Rated travel deviation

2.5%

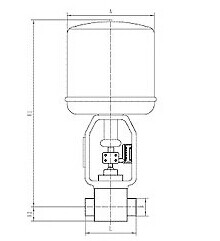

6、 Installation size

Valve diameter

L

Equipped with electric power

H1

H2

A

3/8”

DN10

eighty

five hundred and twenty

twenty-six

two hundred and thirty

1/2”

DN15

eighty

five hundred and twenty

twenty-six

two hundred and thirty

3/4”

DN20

ninety-two

five hundred and eighty

thirty

two hundred and thirty

1”

DN25

one hundred and eleven

five hundred and eighty

thirty

two hundred and thirty

Due to product improvements, technological innovations, or special requirements, the connection dimensions of various valves may change. Please contact our technical department for the latest product information. We can also customize valves with special structural dimensions according to your on-site requirements. The flange welding groove and other size connections of the valve shall comply with the relevant requirements of various standards.

Seven methods for use, maintenance, and troubleshooting

1. Installation and use

Failure to install regulating valves that do not meet requirements can result in significant waste. Conversely, proper installation can ensure normal operation and extend their service life. Reduce maintenance workload and achieve good system control performance.

(1) The installation of regulating valves should generally consider the following aspects:

① Safety: The safety of personnel and equipment during the installation process.

② Control performance: The pressure loss of the piping system should be consistent with the pressure loss considered when calculating the size of the regulating valve to ensure the required flow characteristics. Import and export should strive to ensure sufficient straight pipe sections.

③ Installation location: There should be sufficient space for manual operation by operators (including bypass operation) and the possibility of on-site disassembly and maintenance of regulating valves and accessories.

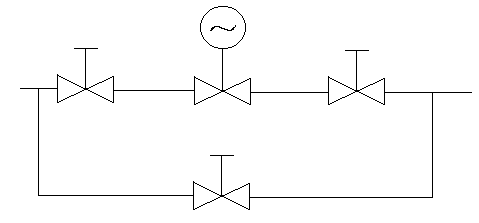

④ Regulating valve group: Generally, bypass valves with shut-off valves are installed in the process piping to form a valve group with regulating valves, in order to meet the needs of continuous operation of equipment. Use a shut-off valve to isolate the regulating valve during maintenance. Adjust with a bypass valve. The recommended arrangement of the regulating valve group in the following figure.

Installation legend of bypass pipeline

(2) On site installation

The installation personnel should first recognize that the regulating valve is a precision instrument and equipment, and should not collide or fall to avoid damage. Please pay specific attention to the following points:

① It is best to install the valve upright and vertically on the pipeline. In situations where the valve has a large self weight and there is vibration, a support frame should be added.

② The valve body should avoid being subjected to excessive stress due to significant differences in axis between the front and rear piping or the flanges being adjusted.

③ Before the initial start of work and after shutdown maintenance, the piping system should be flushed first before installing the regulating valve. Or install a transition filter in front of the valve.

④ The regulating valve must be installed according to the arrow indicating the flow direction on the valve body.

2. Fault analysis and troubleshooting

Common fault states

Cause of malfunction

Exclusion method

The motor does not operate

No power input

Disconnected or disconnected wires

Different and low power supply voltages

The capacitor is broken down

Different input signals

Thermal protection action. (High ambient temperature, high frequency of use)

turn on electricity

Replace the wires or connect the wires correctly

Check the voltage with instruments

Replace the power capacitor

Change input signal selection

Reduce the surrounding temperature, lower the frequency of use or sensitivity

Valve does not operate

The valve core and liner or valve seat are stuck

Valve core detachment, valve stem bending or breaking

Disassemble and reassemble

Replace the valve stem or pin

Manual operation is laborious

The packing gland is too tight

Abnormalities occur inside the valve

Loosen the pressure cover

Disassemble the valve for inspection

Stop during automatic adjustment process

Overloaded starting under excessive load

Thermal protection action

Foreign objects enter the valve body

The packing gland is too tight

Check the regulating valve to eliminate the load

Check the regulating valve to eliminate the load

Disassemble the valve

Loosen the pressure cover

Do not send an opening signal

Poor contact or disconnection of the opening signal wiring

Check the connection of the opening signal wiring

The opening signal cannot reach full closure

Poor installation of potentiometer

Check the installation of the potentiometer

The motor does not stop rotating when reaching the limit position

Poor adjustment of limit switch limit position

Poor installation of limit switch

Readjust

Reinstall

Common fault states

Cause of malfunction

Exclusion method

Adjustment sensitivity decreases, motor torque decreases

Insufficient voltage of the motor, low or different voltage of the power supply

Check the voltage with instruments

The regulating valve oscillates at any opening

Unstable support

There is a vibration source nearby

Wear of valve core and bushing

Strengthening support

Take measures to reduce and eliminate vibration

Adjust and eliminate wear gaps

Slow action of regulating valve

Blockage or coking caused by mud or highly viscous media inside the valve body

Sealing PTFE packing has hardened and deteriorated

Wash the inner cavity of the valve body

Replace the packing material

The valve leaks significantly when fully closed

The valve core or seat is corroded or worn

The thread on the outer circle of the valve seat is corroded

Replace the parts

Replace the parts

Leakage at packing and connection points

The cover is not tightly pressed

Aging and deterioration of PTFE filler

Valve stem damage

Tighten the hexagonal nut and loosen it

Damaged sealing gasket

Tighten the connecting bolts

Replace the packing material

Replace the valve stem

Re tighten the connecting bolts

Replace the sealing gasket

3. Maintenance and Repair

(1) Maintenance

① Regularly inspect the pipeline for rust, welding slag, dirt, and dust.

② Regularly check the support frame for heavy weight and vibration situations.

③ The power supply must not have any malfunctions.

④ The sealing gasket at the connection between the valve body and the upper valve cover has been used for a long time and should be replaced in a timely manner. To replace it, simply remove the upper valve cover and place a new sealing gasket.

⑤ If there is leakage in the packing box, the sealing packing should be replaced in a timely manner. When replacing, the valve stem should be disconnected, the pressure plate and packing cover should be removed, and new packing can be installed.

⑥ Regular maintenance.

⑦ When parked for a long time, protective covers for connecting flanges should be installed, so all interfaces should be plugged with plastic plugs. When parking, ensure the overall verticality or horizontal position of the valve,

⑧ Do not support the valve in sensitive areas such as valve positioners, fittings, wiring, etc.

(2) Repair

When the regulating valve cannot meet the operating requirements during use, or undergoes regular inspections to prevent accidents after a long period of operation, it must be carefully repaired. The maintenance work usually includes the following main contents:

① Valve cleaning - When repairing a valve removed from a process pipeline, all components that have been immersed in the process medium must be cleaned thoroughly. To prevent damage to personnel and equipment caused by corrosive or other harmful fluids. At the same time, the rust on the exposed surface of the components should be removed.

② Valve disassembly - to inspect all components and determine the scope of repair and replacement. Firstly, the actuator and valve should be completely disassembled. When disassembling, it is necessary to protect precision machined parts such as valve cores, valve seats, valve stems, push rods, shaft sleeves, and all precision machined surfaces of the components to prevent damage and minimize maintenance costs. Special tools should be used to disassemble valve seats.

③ Maintenance of main components - if there are small rust spots and wear on the throttling surface of the valve core and the sealing surface of the valve core and valve seat. It can still be repaired using general mechanical processing and grinding methods. If the damage is severe, new parts must be replaced. During repair, it is required to ensure the coaxiality of the valve core and valve seat.

The sealing surface of the valve stem is damaged and can only be replaced with new parts.

Damage to the guiding and sealing surfaces of the push rod. The reaction actuator must be replaced with new parts. And for the positive actuator, appropriate repairs can still be made.

If cracks or other defects affecting the strength are found during the maintenance of the compression spring. Then a new replacement must be used.

④ Replacement of vulnerable parts - The vulnerable parts of this regulating valve mainly include packing, O-ring seals, gaskets, diaphragms, and other components.

During each maintenance, the disassembled packing, O-ring, and gasket must be replaced with new parts. After removing the diaphragm, it is necessary to check for any cracks, aging, and signs of wear that may indicate possible rupture, and then decide whether to replace them based on the specific situation. Generally, it must be replaced within 2-3 years at most.

⑤ Assembly and debugging - During assembly, appropriate lubricating grease should be applied to the positioning, guiding, and threaded connection parts of the components to facilitate disassembly for the next maintenance. Moreover, special attention should be paid to the coaxiality of the push rod, valve core components, and valve seat in the entire machine.

After installation and debugging are completed, the product must pass the factory test items specified in the standard before it can continue to be installed and used.

8、 Transportation and Storage

1. Before storage and transportation, check whether various signs are complete, intact, clear, and whether the packaging boxes are neat and firm, without damage or cracking. Finally, check the reliability and safety of the nail box wrapping.

2. During transportation, it should be loaded and unloaded gently, and throwing, sliding, and impact are strictly prohibited. All types of signs must not be lost, dampened, or damaged.

3. Stored indoors at an air temperature of 5-40 ℃ and a relative temperature not exceeding 90%, the air does not contain harmful impurities that corrode valves.

4. Place according to the markings on the surface of the packaging box and do not invert.

5. The rust prone parts of the product are coated with rust proof grease and wrapped with rust proof paper, with a rust proof period of not less than one year.

6. There should be petroleum asphalt or plastic film inside the packaging box as a rainproof measure.

7. The product packaging has a protection period of one year from the date of leaving the factory.

9、 Unpacking and Inspection

1. After the product is transported to the user, open the packaging box, lift it steadily, handle it carefully, and open the grease paper on the flange hole to install and use it.

2. The packaging box should include the product user manual, product packing list, product qualification certificate, and product quality tracking card.

To meet the requirements of user product completeness, valve positioners, handwheel mechanisms, pressure reducing valves and other accessories can be supplied in sets.

10、 Ordering Notice

1. Product model and name; 2. Nominal diameter DN (mm); 3. Nominal pressure; 4. Traffic characteristics; 5. Valve body material; 6. Rated flow coefficient; 7. Type of medium and temperature range; 8. Pressure difference before and after the valve; 9. Power supply voltage and control signal; 10. Other special requirements.