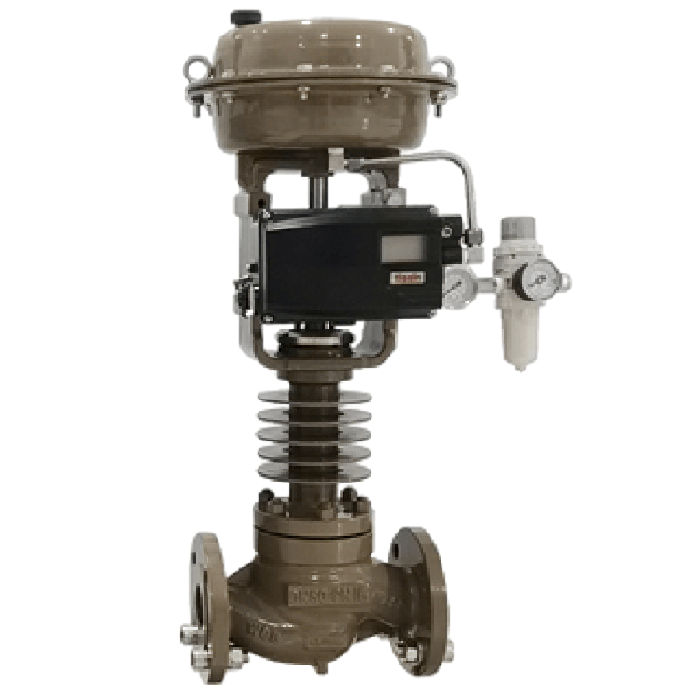

Pneumatic thin film heat sink high-temperature regulating valve is a type of valve that can be used under high pressure and high temperature conditions. Adopting a high-temperature heat dissipation design, the elevated upper valve cover and heat sink structure ensure the safe operation and use of the actuator and electrical valve positioner. The top guided single seat regulating valve is adopted, which has the characteristics of simple structure, good sealing performance, large flow rate, and reliable use.

Pneumatic thin film heat dissipation plate high-temperature regulating valve can be widely used to control fluids of various pressures and temperatures. The valve body structure is compact, the fluid channel is S-shaped, and it has the characteristics of low pressure drop loss, large flow flux, wide adjustable range, and high accuracy of flow characteristics. The valve core of the pneumatic thin film heat dissipation plate high-temperature regulating valve has a rich Cv value, and the sealing performance of the valve seat meets the international industry standards for regulating valves. The regulating valve is equipped with a multi spring thin film actuator, which has a small structure and high output force, and is more suitable for small flow control in high-temperature applications that require high reliability and closing performance. Widely used in production automation control of industrial sectors such as power, metallurgy, chemical, petroleum, printing and dyeing, textile, pharmaceutical, papermaking, etc. Valve body form: Straight through spherical regulating valve Valve diameter: 20-500mm nominal pressure: PN1.6, 2.5, 4.0, 6.4, 10.0 ANSI Class 125, 150, 300, 600 JIS 10K, 16K, 20K, 30K, 40K Connection Form: Flange FF, RF, RJ and LG Standards According to: ANSI BI6.5, JIS B2201, HG20592-2009 Welding Type: Socket Welding SW (20-25) Threaded Connection: (Rc1/2 "~1") Material: WCB WC6 CF8 CF8M CF3 CF3M