As the name suggests, metal hard sealed ball valves use metal materials as the valve seal, usually with the valve body material as the valve seat. If high temperature, wear resistance, and corrosion resistance are required, some alloys such as chromium carbide, Stellite, and tungsten carbide are also used as sealing materials. Due to its characteristics of low fluid resistance, smooth flow path, rapid opening and closing, and easy automatic control, ball valves are widely used. Conventional ball valves are equipped with PTFE and other valve seats, but due to the characteristics of non-metallic sealing materials, the application of ball valves in high temperature conditions is limited and can only be used within a very limited temperature range. In this situation, new practical hard seal ball valves have emerged, overcoming temperature limitations and widely used in the petrochemical industry, power, metallurgy, and light industry. Hard sealed ball valves are used to cut off or connect media in various pipelines. Hard sealed ball valves are also suitable for harsh environments such as solid particles, mud, coal powder, coal slag, etc.

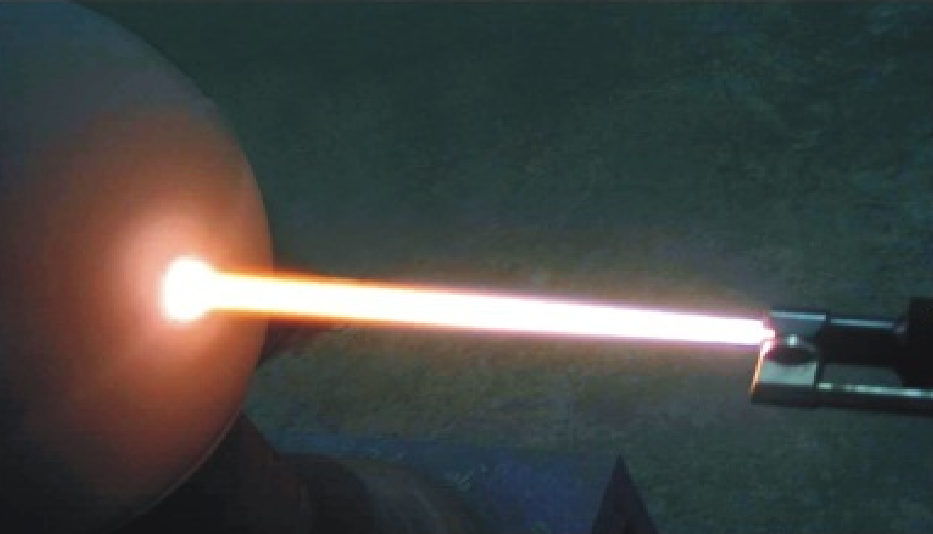

The ball and valve seat are completely sealed using a "metal metal" sealing mode. Various advanced quenching processes such as HVOF (High Speed Flame Spraying), nickel based alloy spray welding, high nickel alloy spray welding, drill based alloy spray welding, etc. are targeted for various media environments and user requirements. Generally speaking, the hardness of the sealing surface of the ball and valve seat can reach HRC55-60. The highest hardness of the valve is HRC70. The heat-resistant temperature of the sealing surface of the ball and valve seat can reach 540C, while the highest heat-resistant temperature of the valve is 980C. In addition, the sealing surface material also has excellent wear resistance and impact resistance.

Under the influence of medium and high temperature, the ball and valve seat will deform due to thermal expansion, causing the valve to fail to open normally. The ball valve adopts a butterfly spring or spring pressurized sealing structure, which can absorb the heat of the valve parts by the butterfly spring or spring under high temperature conditions. This allows the valve to not expand or deform under high temperature conditions and ensures the flexible opening and closing of the valve.